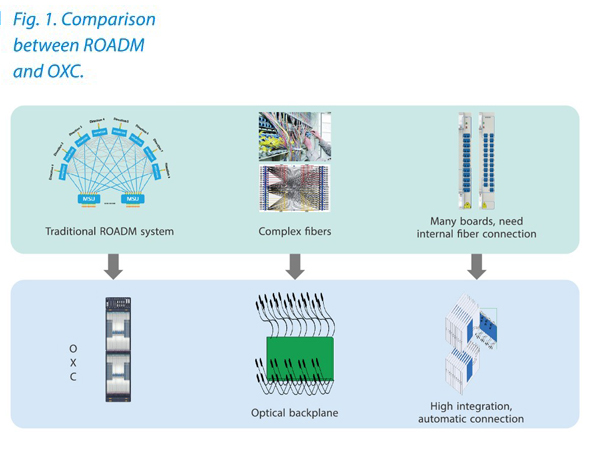

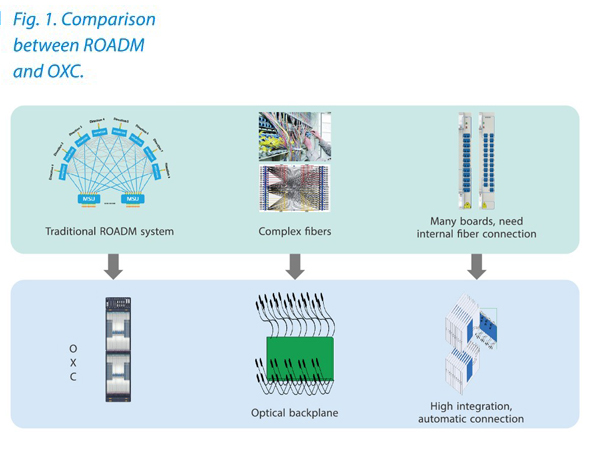

ROADM can implement multi-degree large-capacity wavelength-level scheduling to meet the networking demands of backbone, metro and data center interconnection (DCI). However, as the degrees of a ROADM grow, the number of fiber connections inside the ROADM site increases dramatically, which makes the service provisioning and maintenance process time-consuming, prone to human errors and increases the footprint and power consumption. Optical cross-connect (OXC) addresses these problems by using the all-optical backplane in combination with the highly integrated optical line boards and optical add/drop boards. Since 2018, OXC has been widely used by Chinese operators.

Composition of OXC and Key Technologies

A 20-degree ROADM requires three cabinets, more than 100 boards, and 400 fibers inside the site. It occupies a large area and has high power consumption and complicated fiber connection, making service provisioning and maintenance difficult. As the number of degree increases to 32, the footprint, power consumption, and the number of fiber connections will increase dramatically, and it will be difficult to locate problems due to a large workload of service provisioning and maintenance. Compared with ROADM, OXC uses highly integrated boards and optical backplane to reduce the footprint and power consumption and simplify internal fiber connections (Fig. 1). A 20-degree OXC needs only one cabinet to reduce the footprint by 2/3 and about 30 boards to reduce the number of boards by 2/3 while also reducing the corresponding power consumption. The optical backplane connects all fibers inside the site to achieve automatic fiber connection, which improves the provisioning efficiency and reduces the maintenance costs.

An

OXC is mainly composed of a optical backplane, optical line boards and optical add/drop boards, and involves key technologies like flexible optical backplane, high-density optical connector, 1×N wavelength selective switch (WSS) and M×N WSS. The optical backplane includes a flexible optical backplane and high-density connectors. The optical add/drop boards have two types: with colorless, directionless, flexgrid (CDF) capability or with colorless, directionless, contentionless and flexgrid (CDC-F) capability. The first type employs TWIN 1×N WSS and does not support contentionless functionality. It integrates the WSS and the optical amplifier, and occupies one slot. It can add/drop 32 wavelengths and schedule a service to any optical direction through the high-density connectors and fiber connections on the optical backplane. The latter type employs M×N WSS and occupies two slots. It supports contentionless add/drop of 48 wavelengths in 8/16 degrees. The optical line board highly integrates the OA, OP, OSC and OTDR function modules, and one slot corresponds to one direction. One optical line board occupies one slot and corresponds to one direction. The optical line board is connected with the optical backplane through the high-density connectors and can schedule a group of wavelengths to any optical direction or any optical add/drop board for service add/drop.

—Optical backplane: The optical backplane technology is used to convert internal fibers between optical interfaces of the ROADM board into high-density interconnected fibers on the optical backplane. Internal fibers are divided into multiple groups, deployed through the fiber cabling machine and encapsulated into a flexible plate to form a flexible optical backplane that supports non-blocking fiber connections.

—High-density connector: The optical backplane is connected with the optical line board and optical add/drop board through the high-density connector. The optical connector must have high density to ensure full interconnection of all optical boards inside the OXC site and also support blind insertion with features like high interconnection precision and reliability of multiple plugging/unplugging.

—WSS: The core components of optical add/drop boards and optical line boards are 1×N WSS and M×N WSS. The related technologies mainly include micro-electro mechanical system (MEMS) and liquid crystal on silicon (LCoS).

HTF help customer to choose the suitable solution and save cost. If need support, welcome to contact. www.htfuture.com ivy@htfuture.com +8618123672396